Materials

If you need a rubber material for your project, we can custom create it for you.

We know what material is right for the job.

We can process a wide variety of rubber materials. More importantly, we know when each one is right for the job. Years of research, testing, design engineering and real-world applications have given us an incredible depth of knowledge about how polymers behave when put through different molding processes. And how they’ll work under just about any condition in any application. We work with our customers to help them make the best decision on the material to be used in their specific product.

Here are just a few of the materials we commonly process:

- Nitrile (Buna-N)

- EPDM

- Fluorocarbons (Viton, Aflas, etc.)

- Fluorosilicone

- Neoprene

- Butyl

- Silicone

- SBR

- Hydrin

- Hypalon

Check out our Elastomer Reference Guide

Methods

We can fabricate your custom rubber products using compression, injection or transfer molding, in addition to extrusion. We’ll work with you to determine the best method based on your budget, the product’s size and configuration, the material to be used and the number of pieces needed. We can even quote a number of different scenarios to help you plan your project as accurately as possible. We also offer secondary services that can make your rubber product ready for use as soon as it hits your dock. These include PTFE coating, secondary machining, slitting and notching.

Learn more about each of our methods below.

Mold Design

Mold designing is a process where engineers come together to create a specific rubber part design. This part can be a component on a machine or mechanical device, or a simple connective part or seal.

Mold Making

Mold making is the process used to manufacture a part or product by shaping pliable rubber compounds using a rigid frame called a mold or matrix.

Injection Molding

While the tooling costs are not as low as with compression molding, injection molding offers several advantages. It’s perfect when you need high precision for low-cost parts. It’s also the best choice when dealing with very high volume – quantities ranging from the hundreds of thousands into the millions.

Compression Molding

Ideal when you need rapid turnaround. The tooling costs are relatively inexpensive when compared to other molding processes, and the material waste is minimal.

Transfer Molding

Ideal for medium quantities ranging from 500 to 100,000 pieces. The tooling costs are a little higher than those associated with compression molding, but are lower than injection molding while delivering the same kind of precision.

Extrusion Molding

Given its ability to produce a variety of neat and uniform parts, the extrusion process has become a popular choice for many manufacturers, in various applications. Extrusion not only brings consistency to the table, it can also greatly reduce the amount of material used when producing hollow designs. Further, this reduction in material allows extruded rubber parts to be both flexible and lightweight. Some of the most prevalent extruded rubber products include bumpers, bushings, cords, diaphragms, gaskets, tubing and hose, stripes, and profiles.

Flashless Molding

Flashless molding is a process of manufacturing parts with no excess material, or flash. Flashless molding can be more expensive than more traditional molding processes, but the benefits are often worth it.

Insert Molding

Both insert molding and overmolding involve putting two types of materials together to make one part.

Overmolding

Overmolding lets you combine multiple materials into one part. One material, usually a thermoplastic elastomer, is molded onto a second material, which is often a rigid plastic. An example is a toothbrush handle where the single piece has both rigid and rubbery components. It’s a great way to make plastic parts perform and look better.

Encapsulation Molding

Encapsulation molding is a process for molding rubber compounds onto a base material. This could be a wire, housing, or handle to create a finished product or part.

Insert Compression Molding

Insert compression molding differs from standard insert molding because the rubber material is “pressed” under pressure into a mold, rather than “injected” into a mold.

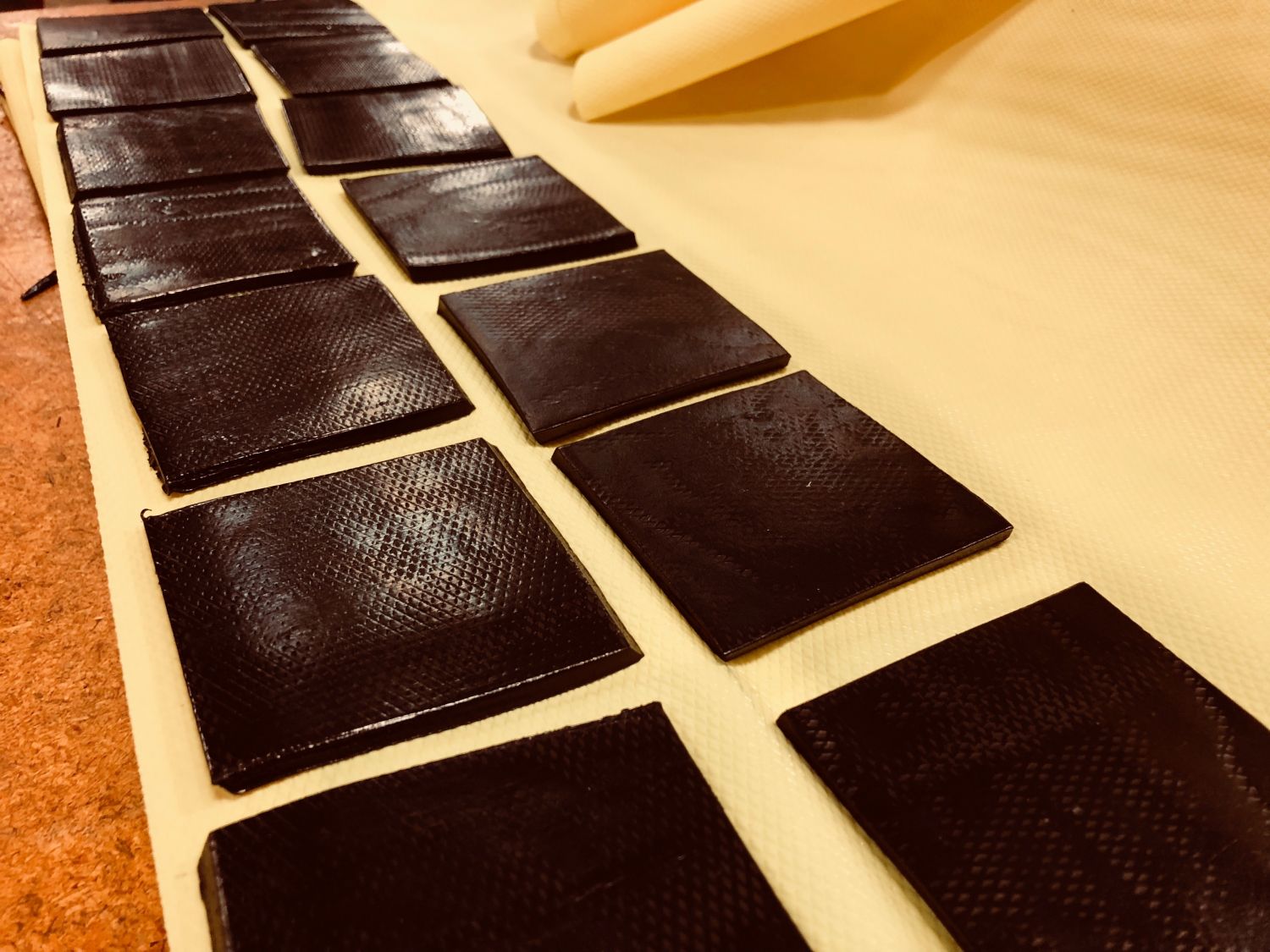

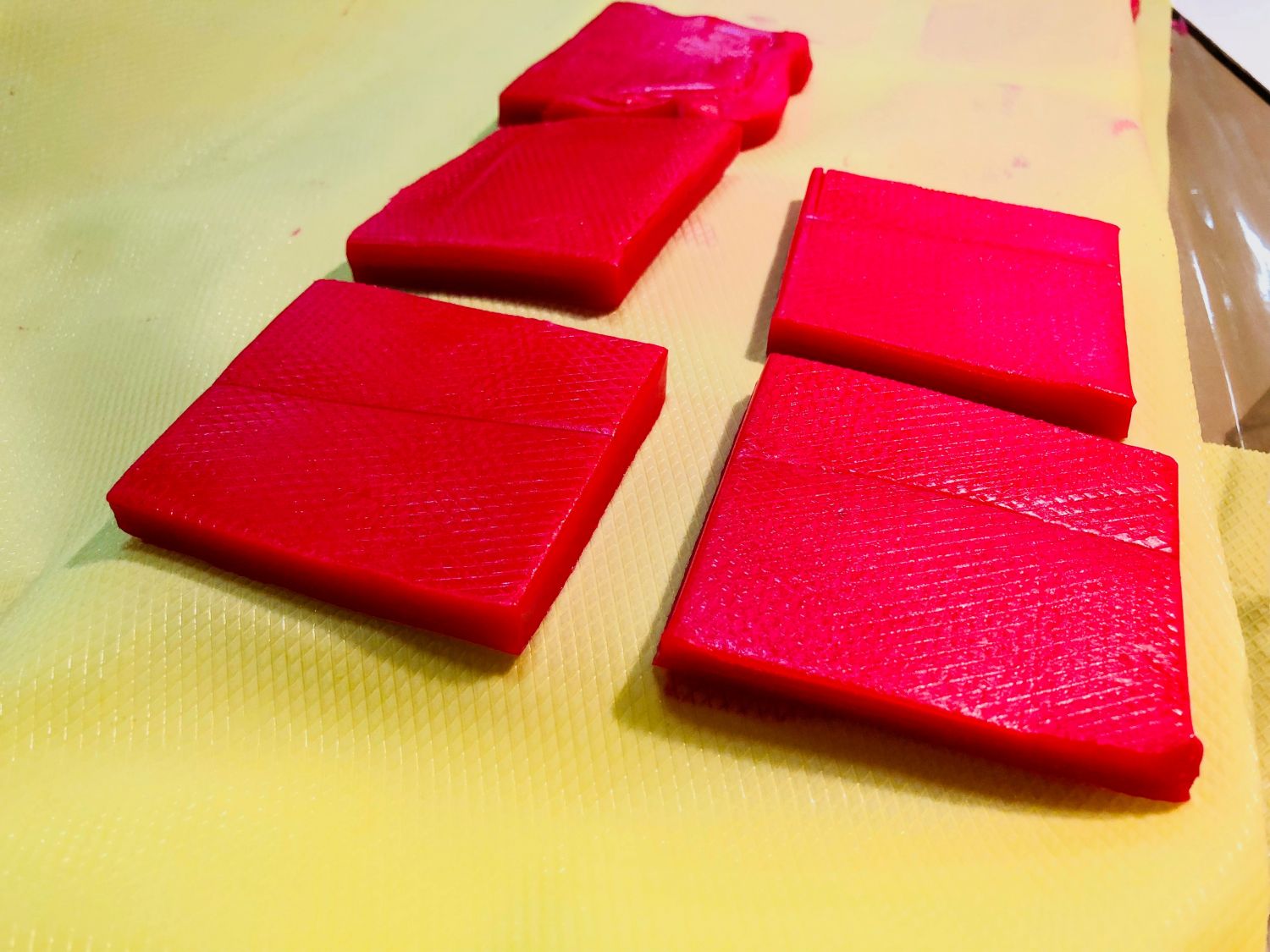

Flat Molded

Discover more about flat molding methods at the link above.

Direct Compression Molding

In direct compression molding, a polyethylene insert (or other material) converts rubber or other compounds to a finished or semi-finished part using individual molds.

LET’S GET STARTED ON YOUR NEXT PROJECT.

Call (330) 270-9780 or request your free quote here.