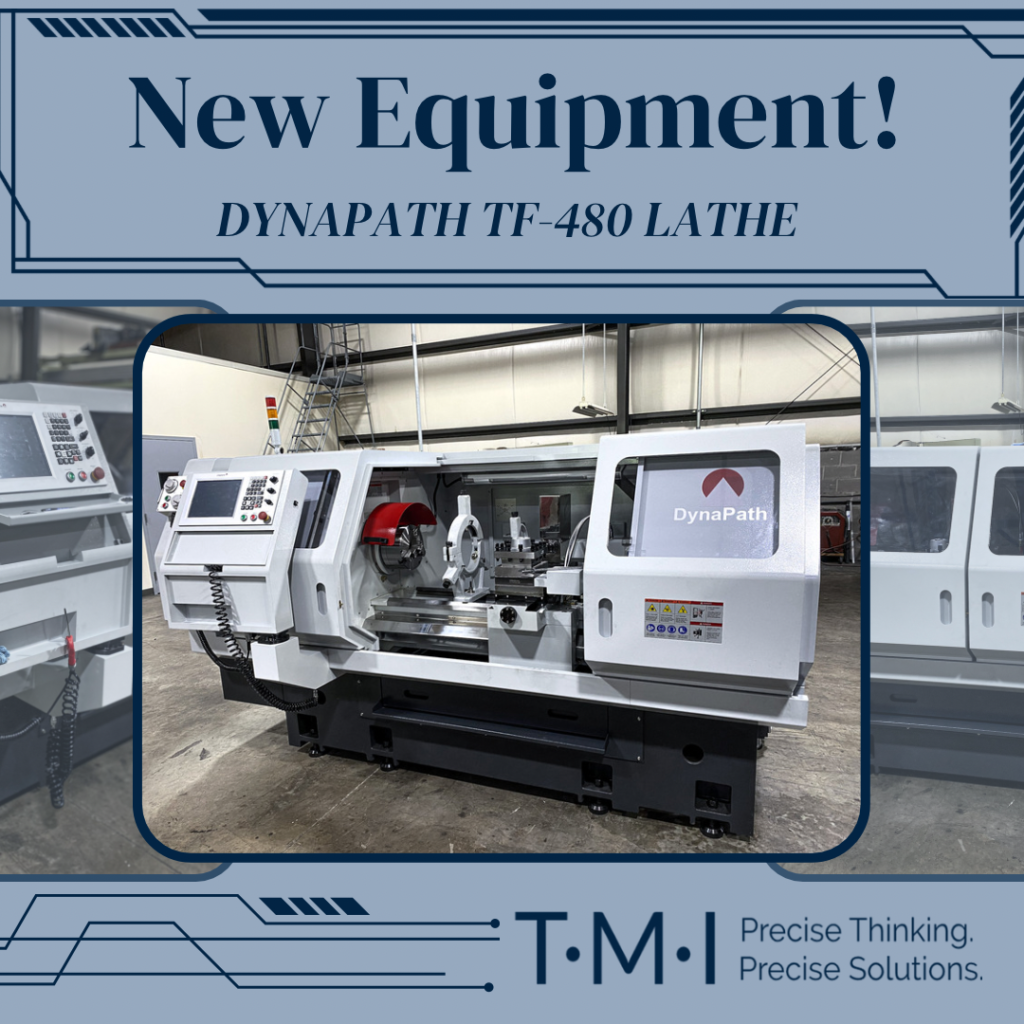

As a leading rubber manufacturer, we constantly strive to push the boundaries of innovation and quality in our industry. That’s why we are thrilled to announce our recent acquisition of the state-of-the-art Dynapath Lathe for our in-house machine shop. This cutting-edge technology promises to revolutionize our manufacturing process, allowing us to enhance precision, efficiency, and overall product quality. In this blog post, we will delve into the exciting features and benefits of the Dynapath Lathe and explore how it empowers us to deliver even better rubber products to our valued customers.

Introduction to the Dynapath Lathe:

The Dynapath Lathe is a highly advanced computer numerical control (CNC) lathe machine, designed to meet the demands of modern manufacturing processes. It combines advanced software, high-precision components, and intelligent automation to streamline the machining of tooling and metal components. With its exceptional capabilities, the Dynapath Lathe has become a game-changer in the world of manufacturing.

Precision Engineering for Superior Quality:

One of the most significant advantages of the Dynapath Lathe is its exceptional precision engineering. This cutting-edge technology ensures that our tooling and parts are machined with unparalleled accuracy and consistency. The lathe’s sophisticated control system allows us to achieve tight tolerances, intricate geometries, and superior surface finishes, resulting in high-quality products that meet or exceed our customers’ expectations.

Increased Efficiency and Productivity:

The Dynapath Lathe’s advanced automation and intuitive software significantly improve our manufacturing efficiency and productivity. By automating repetitive tasks and optimizing tool paths, we can reduce production cycle times, increase throughput, and minimize human error. This allows us to deliver products to our customers in a more timely manner, enhancing overall customer satisfaction.

Versatility and Flexibility:

Our investment in the Dynapath Lathe has also enhanced our ability to handle a wide range of machining requirements. This versatile machine is capable of machining various materials and can accommodate different shapes, sizes, and complex geometries. This versatility enables us to serve diverse industries and fulfill custom orders with ease, expanding our market reach and providing tailored solutions to our customers.

Streamlined Workflow and Quality Control:

The integration of the Dynapath Lathe into our in-house machine shop has streamlined our workflow and improved our quality control processes. The machine’s advanced monitoring and diagnostic features allow us to track key parameters in real-time, ensuring that each component is manufactured with precision and consistency. Additionally, the lathe’s comprehensive data logging capabilities enable us to analyze and optimize our machining processes continuously, leading to further improvements in product quality and operational efficiency.

The integration of the Dynapath Lathe into our in-house machine shop marks a significant milestone in our continuous pursuit of excellence. With its advanced precision engineering, automation capabilities, and versatility, this cutting-edge technology empowers us to manufacture products of superior quality, while also improving efficiency and productivity. We are excited about the possibilities that the Dynapath Lathe brings, and we are confident that this investment will benefit both our business and our customers. As we embrace this new era of precision machining, we look forward to further elevating our position as a leading rubber manufacturer in the industry.

If you have questions about our capabilities, contact us!